UNI’s MCC is advancing advanced manufacturing

The phone in your pocket.

The car you drive.

The refrigerator in your kitchen.

More than 95% of the durable goods produced in North America have metal casting involved in its manufacture. There is a good chance that the Metal Casting Center (MCC) at the University of Northern Iowa (UNI) has impacted one of your products.

Established in 1989, the MCC has become a nationally recognized industry leader. Since its creation, the center has expanded to include an Additive Manufacturing Center (AMC), featuring North America’s largest 3D printer. With more than 40 years in advanced manufacturing, MCC Director Jerry Thiel takes great pride in the impact the center has made in an industry that touches so many aspects of daily life.

Can you describe the purpose of each of the two facilities?

The MCC is helping the advanced manufacturing industry with research and development projects involving hot metal. When new products are developed at companies throughout the United States, we assist them with evaluating those products for commercialization.

At the AMC, we use state-of-the-art 3D printers and our core strengths to advance technology in the metal casting industry. There, we’ve helped a wide range of companies — from someone needing a replacement part for an antique combine, to creating parts for the prototypes of space rocket engines.

How has the Metal Casting Center impacted the university?

When the MCC first opened, UNI received a lot of notoriety and has since been a great recruitment tool. When students come here, we give them design skills, confidence and hands-on experience. The wonderful thing about the MCC is, although supervised by full-time staff, all work is done by students. As our students are trained, they become extremely valuable and highly recruited when they graduate.

What is the biggest issue in the manufacturing industry today and how is the MCC helping to solve that?

One of the largest problems that manufacturing has is a sustainable workforce and finding quality, skilled people to do the work. What we need, and what the industry is asking for, is automation to replace those jobs that are dirty, dark and dangerous. We must get smarter to make these jobs better resulting in higher employee retention in the industry.

Manufacturing 4.0 is beginning and will revolutionize the industry. It includes computers, robots, automation and technology including sensors that can sense every environmental or work condition in the company. We truly are on that cusp of more automation, especially in the small- to medium-size companies. Here at the MCC, we are driven to be the leader and help those companies’ transition.

Public service is a major part of the MCC. Can you explain what all that entails?

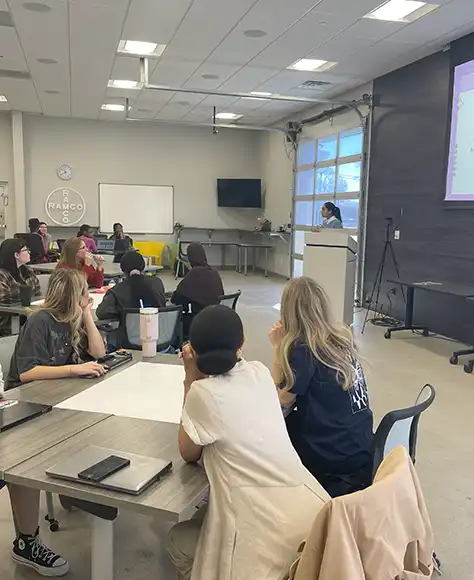

About 10%-15% of the work we do, we consider public service. In 2019, we had nearly 1,000 visitors at the AMC alone. These visitors consisted of state legislators and companies from around the county that want to see firsthand the technology we are utilizing. The visitors also included middle school and high school students interested in possible careers in advanced manufacturing.

Specifically, the mentoring has been extremely successful. We have found that many of our young visitors have a passion to build and make things. When they can design it digitally and then manufacture it the same day with additive manufacturing — it is fun to watch. I think we are providing great value to the industry not only today but will in the future as well.

Learn more about the University of Northern Iowa Metal Center or schedule a visit at mcc.uni.edu.