From Passion to Product

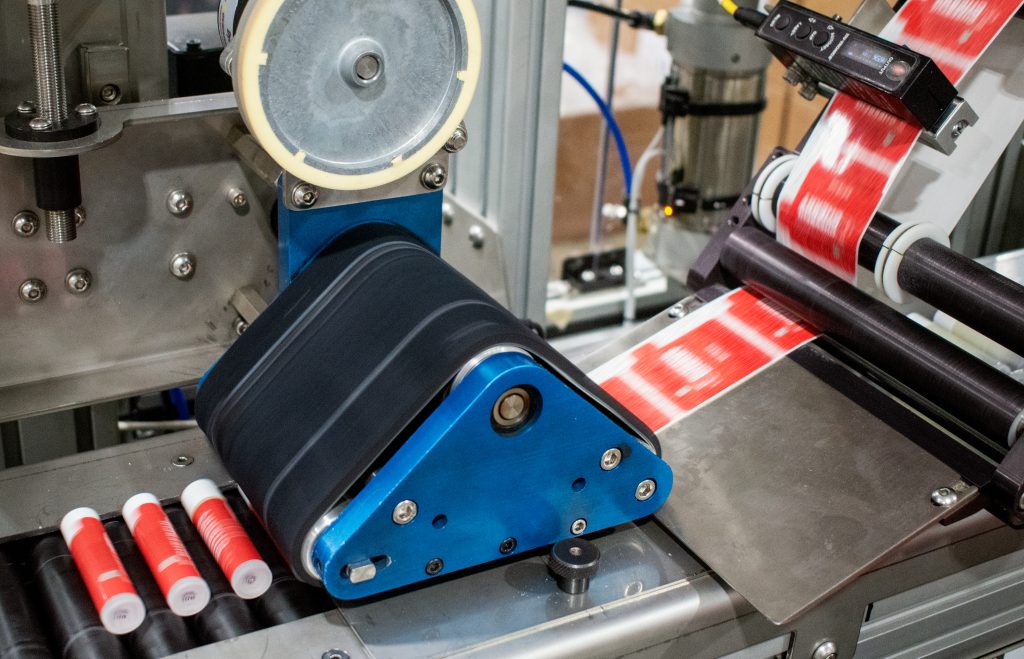

When touring Eco Lips’ 90,000-square-foot manufacturing plant, it’s hard to imagine the lip balm brand’s humble beginnings on an apartment stovetop. It’s since grown into an 80-employee operation inside a Cedar Rapids facility that’s powered by renewable energy. Fully and semi-automated production lines now fill more than 30,000 tubes an hour while a high-tech system optimizes every step of the process.

Producing lip balm on such a large scale was only a dream in the minds of founders Steve Shriver and Andrea Danielson in the mid-90s. They were a young, outdoorsy couple who valued adventure paired with sustainability – Andrea used to whip up small batches of balm on the stovetop for Steve to take with him while guiding mountaineering treks.

“That was when all the bells started going off,” said Steve, who can trace his salesman spirit back to selling bubblegum on the playground. “I thought, ‘This is the product I’ve been waiting for.’”

When Steve suggested he could turn Andrea’s hobby into a business, she didn’t bat an eye. They both grew up in entrepreneurial families and were inspired to take the leap. With $5,000 from Andrea’s savings, the couple bought tubes and labels and started peddling product to shops throughout Cedar Rapids.

“I don’t think either of us really understood what [that early business] would become,” Steve said. “It wasn’t like, ‘I’m going to make this into a multimillion-dollar company.’ It was, ‘I’m going to start selling this lip balm and let’s try to make a living off of it.’”

The couple expanded their startup into a specialized private label natural body care company they named Raining Rose after their two daughters. It quickly became a leading manufacturer in the emerging natural products industry and, five years later, they sold it for $1.2 million.

While still in his 30s and hungry to build his own brand, Steve then founded Eco Lips to fill a gap he saw both in the lip balm and organic markets, thus creating the first lip balm to use organic ingredients.

“We thought if we could get people try this lip balm, they’d be more open to organic brands,” Steve said. “We were creating change in the country and world through our small products.”

As CEO, he also led the company to pursue its B-Corp Certification. This rigorous process requires a company to participate in assessments to evaluate how its business impacts stakeholders and the environment, providing input on where processes can be improved.

“Becoming a B-Corp gave us the framework to understand true sustainability,” Steve said. “It just so happens, too, that the better we do sustainability wise, the more money we make, which is crazy.”

Learning to Fail Forward

Such growth and success do not come easy, and Eco Lips’ 20-year anniversary milestone has created moments for reflection. Throughout the years, setbacks have conversely propelled the company forward. The manufacturer has outgrown multiple locations and rebounded from the floods of 2008 and 2016 to build back bigger and better.

“It’s funny because I’m probably prouder of our failures,” Steve said. “We grew as a company because we offered innovation even though the market wasn’t ready.”

Though early efforts to introduce a paper tube were a flop, launching new products landed them meetings with major retailers like Walmart and Kroger. Those chains wound up purchasing some of their other lines, and Eco Lips got to work perfecting a plant-based tube as an alternative to plastic. The company’s products are now sold in more than 30,000 stores across the United States.

“Twenty years later, it’s still about problem-solving every day to try to get better,” Steve said.

No Place Like Home

Although Steve always envisioned his family living near mountains and originally founded Eco Lips in California, the CEO soon realized their home state offered more opportunities. Steve and Andrea have launched multiple companies in Iowa, including the beloved Brewhemia café in Cedar Rapids’ Czech Village & New Bohemia District.

Eco Lips has also benefited from the Iowa Economic Development Authority’s assistance programs for business expansion and Manufacturing 4.0 investments. This funding helped Eco Lips implement Redzone software, which is already revolutionizing the business by bringing multiple programs under one unified system. The company also acquired tin-filling machinery for a new product that will satisfy customer requests and add revenue and jobs. This specialized equipment and quality assurance commitment help Eco Lips stay competitive in a much more crowded global market.

“There’s no better place to be in business than Iowa,” Steve said. “We considered moving to Colorado, but workforce is tougher to find out there and cost of living is higher. The centralized location of Iowa, the manufacturing infrastructure here – from banks and accountants that understand it, to attorneys that get it, to communities that support and embrace the industry—it is an advantage.”